Minimizing Machine Downtime in Factories with 3D Printing

#Jan 06, 2025

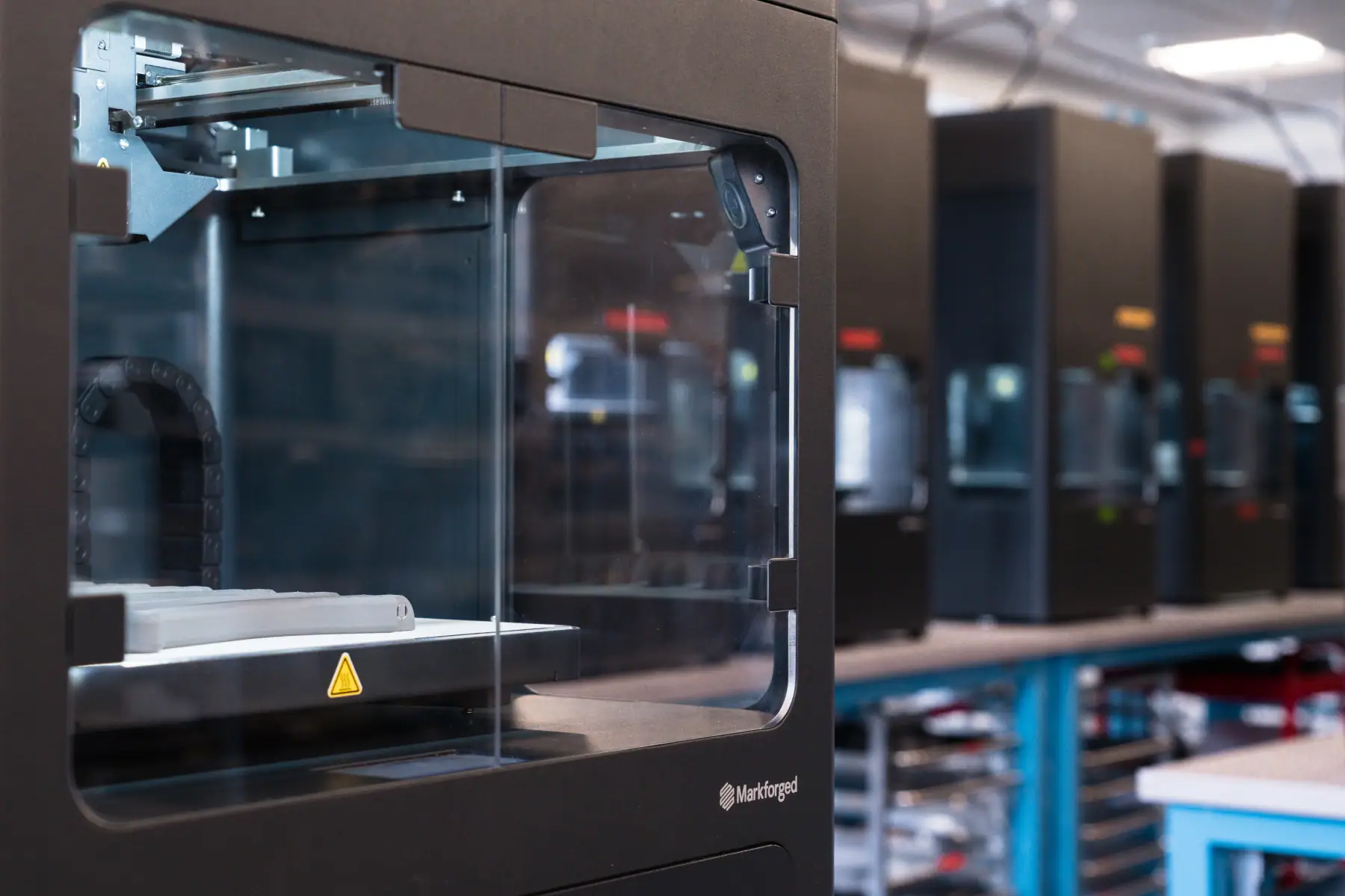

Minimizing Machine Downtime in Factories with 3D Printing

One of the greatest challenges in the manufacturing sector is minimizing downtime caused by machine failures. Interruptions in production lines not only result in time losses but also lead to substantial costs. Traditional spare part procurement processes often face supply chain issues and high logistical expenses, further complicating the situation. At this juncture, 3D printing technology makes a significant difference by enabling rapid spare part production and on-site solutions.

The Role of 3D Printing in Spare Part Procurement

In traditional methods, sourcing necessary spare parts for a malfunctioning machine can take days or even weeks. Instead, with 3D printing technology, factories can produce required parts on-site and quickly. For instance, a German automotive supplier reduced downtime by 50% by 3D printing a specialized connector used on their production line. This avoided millions of euros in costs associated with production loss.

According to a report by Deloitte, companies using 3D printing technology achieve an average of 60% cost savings in spare part production. This presents a significant opportunity not only for large-scale factories but also for small and medium-sized enterprises. For example, a textile factory in China avoided a potential $5,000 loss by producing a malfunctioning machine part in just two hours using 3D printing instead of ordering it externally.

Speed and Flexibility: The Advantages of 3D Printing

When a machine breaks down, supply chain problems and logistical delays often exacerbate the situation. These challenges lead to halted production lines and delayed customer deliveries. However, 3D printing has completely transformed this process. For instance, an aerospace company in the United States produced a critical aircraft component using 3D printing, delivering it 75% faster than traditional methods. This not only sped up the production process but also enhanced the company’s reliability.

In addition to rapid production, the flexibility offered by 3D printing is another significant advantage. An automotive factory in Japan began using 3D printers to produce spare parts of various sizes and shapes instantly during breakdowns. This allowed production to continue seamlessly and maintained customer satisfaction.

Cost and Energy Efficiency

One of the most striking advantages of 3D printing technology is its cost efficiency. While a metal part produced through traditional methods costs around $1,000, the same part can be manufactured for $400 using 3D printing. Similarly, the production time for these parts can be reduced from 10 days to just 2 days.

Moreover, this technology holds immense potential for energy savings. 3D printing consumes up to 50% less energy compared to traditional manufacturing methods, contributing to environmental sustainability goals. The European Union’s 2025 targets include the widespread adoption of 3D printing to reduce energy consumption in manufacturing.

The Impact of 3D Printing Across Various Industries

3D printing is not limited to spare part production; it also drives transformation across entire manufacturing processes. For example, a food processing factory in the UK redesigned a specific machine part using 3D printing. This part became more durable and improved process efficiency by 20%.

In the aerospace sector, companies like Airbus save millions of dollars annually by producing spare parts with 3D printing. Furthermore, this technology supports the aviation industry’s goals to reduce carbon emissions. Parts manufactured with 3D printing are lighter, reducing fuel consumption by 15%.

By 2025, the use of 3D printing technology is expected to become even more widespread. Integrated with technologies like artificial intelligence and the Internet of Things (IoT), 3D printing systems will offer proactive solutions for maintenance and repair processes. For instance, sensors can detect potential machine failures, and the necessary spare parts can be automatically produced via 3D printing before the failure occurs. This approach will minimize both downtime and unexpected costs.