What Is a 3D Resin Printer? Working Principle and Key Features

#Oct 30, 2025

3D printing technology has emerged in recent years as a breakthrough innovation that has revolutionized manufacturing processes. One of the most precise and detailed examples of this technology is production made with a 3D resin printer. Also known as a resin-based 3D printer, this method is particularly preferred in industries requiring high resolution, superior surface quality, and fine detail.

In this article, we will take an in-depth look at the working principles, technical features, and application areas of resin-based printing systems.

Fundamental Principle of Resin 3D Printing Technology

Resin 3D printing works by curing light-sensitive liquid resin layer by layer to create three-dimensional objects. This process is generally carried out using SLA (Stereolithography) or DLP (Digital Light Processing) technologies.

The basic principle is the same for both methods:

- The printer contains a tank filled with liquid resin.

- A light source (laser or projector) projects the cross-section of the model onto the resin surface.

- The resin exposed to light polymerizes and solidifies.

- The build platform moves upward, allowing the next layer to be formed.

Repeating this cycle hundreds of times results in the final 3D model. Compared to thermoplastic-based printing techniques such as FDM (Fused Deposition Modeling), resin printing offers significantly higher resolution.

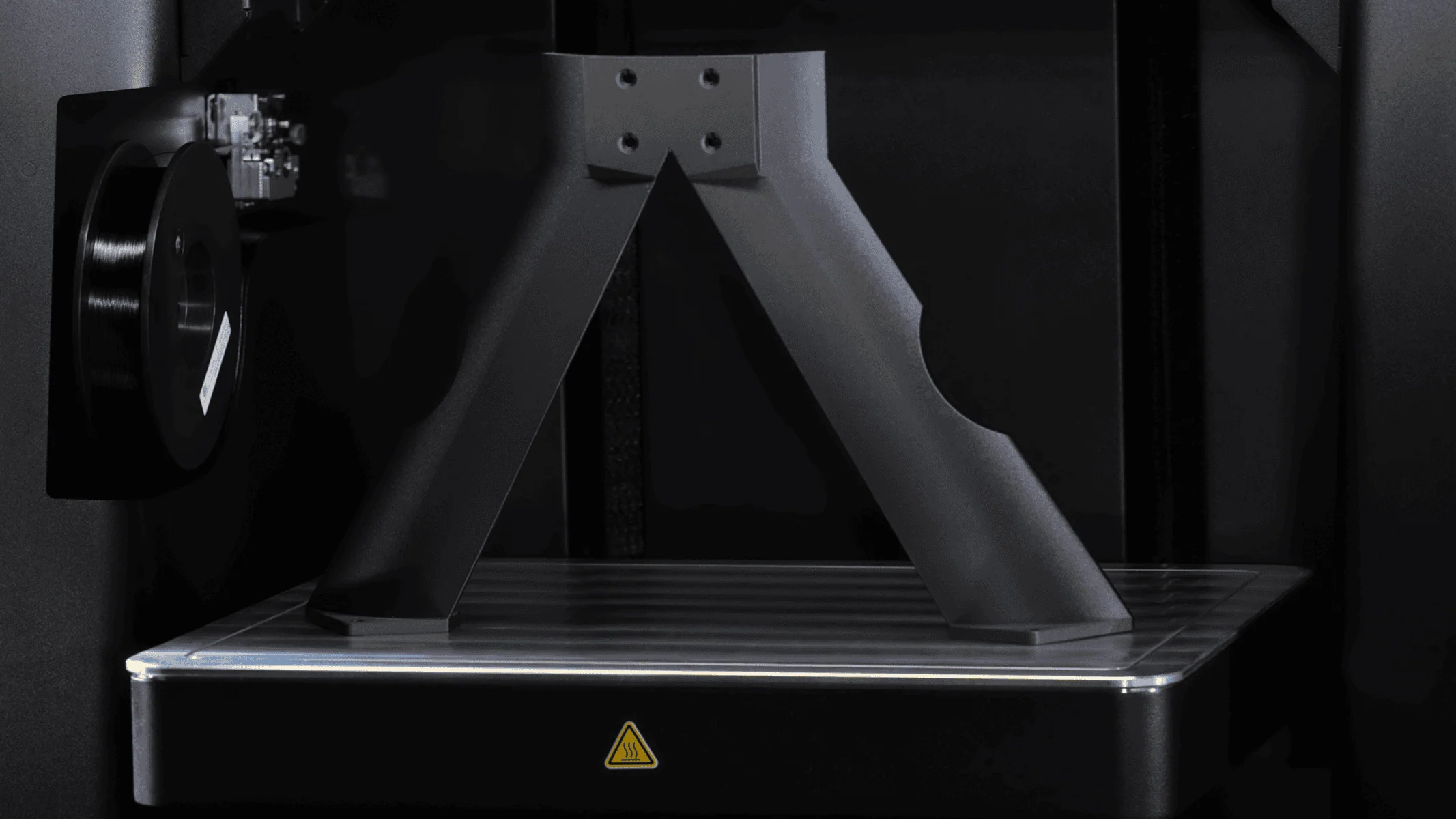

Working Structure of a 3D Resin Printer

A 3D resin printer essentially consists of the following components:

- Resin tank (vat): Contains the light-sensitive liquid resin.

- Build platform: The movable surface on which the layers are formed.

- Light source (laser or LED projector): Provides the energy to cure the resin.

- Control system and software: Convert the digital model into a physical object.

Proper calibration of these systems is crucial for print quality. Parameters such as layer thickness and light intensity are key factors that determine the level of detail and surface smoothness.

Advantages of Resin 3D Printing Technology

Resin printers stand out with their exceptional precision and level of detail. This technology offers several notable advantages:

- High resolution: Micron-level detail production is achievable.

- Smooth surface finish: Prints can be used without post-polishing or sanding.

- Complex geometries: Enables the creation of intricate structures impossible with traditional manufacturing.

- Material versatility: Works with rigid, flexible, or transparent resins.

These properties make resin printing ideal for engineering prototypes, jewelry design, dental modeling, and industrial molding applications.

Materials Used in Resin 3D Printing

The materials used in resin printing are photopolymer resins, which solidify through chemical reactions when exposed to specific wavelengths of light. The most common resin types include:

- Standard resins: Suitable for general prototyping.

- Tough resins: Provide greater mechanical strength.

- Flexible resins: Used for rubber-like parts.

- Transparent resins: Ideal for optical applications.

Advanced resin formulations may also offer properties such as heat resistance or biocompatibility, enabling the use of 3D resin printers not only for prototypes but also for end-use parts.

Key Considerations When Choosing a Resin 3D Printing Service

Before ordering a 3D resin printing service, it is essential to evaluate the technical specifications and production capacity according to the project’s purpose. The following criteria can help guide the selection of a reliable service provider:

- Build volume: Must support the intended model size.

- Resolution (XY and Z axes): Determines the detail level.

- Light source type: Laser-based systems generally offer higher accuracy than LED-based ones.

- Resin compatibility: Flexibility to work with different material types.

- Maintenance and software support: Affect production quality and continuity.

For professional manufacturers, service providers that offer large build volumes and high-resolution SLA printing are ideal. At this point, 3D Promakim’s resin printing services stand out by delivering high-precision solutions across multiple industries — from prototyping to mass production — with wide production capacity and superior surface quality through SLA technology.

Industrial Applications of Resin 3D Printing

3D printing systems are widely used across industries — from prototyping to mold production. Resin-based systems, in particular, create value in the following fields:

- Medical and dental: Precision dental models, surgical guides.

- Jewelry: Detailed mold patterns for fine designs.

- Engineering: Functional prototypes and molded components.

- Art and design: Custom productions requiring high aesthetic surface quality.

These printers improve production speed while minimizing error rates in each of these sectors.

Limitations of Resin 3D Printing

Like any technology, resin 3D printing systems also have certain limitations:

- Require post-processing steps such as cleaning and curing.

- Resin materials are generally more expensive than filament-based alternatives.

- Resins can degrade under prolonged exposure to light or heat.

- Require careful handling and environmental control.

However, with the advancement of resin formulations and printer design, these limitations are steadily diminishing.

Where Precision Meets Innovation

Resin 3D printing technology delivers precision, flexibility, and quality in production. It provides significant advantages over traditional methods, especially in industries that demand high detail and accuracy. With the right equipment selection and material use, a 3D resin printer offers a unique production experience to its users.

If you seek higher quality, efficiency, and flexibility in your manufacturing processes, explore 3D Promakim’s innovative 3D printing solutions to add value to your projects and contact us today to get started.