Markforged FX10: The Industrial 3D Printer That Combines Metal and Composite Manufacturing in One Platform

#Jul 14, 2025

Redefining Flexibility in Modern Manufacturing

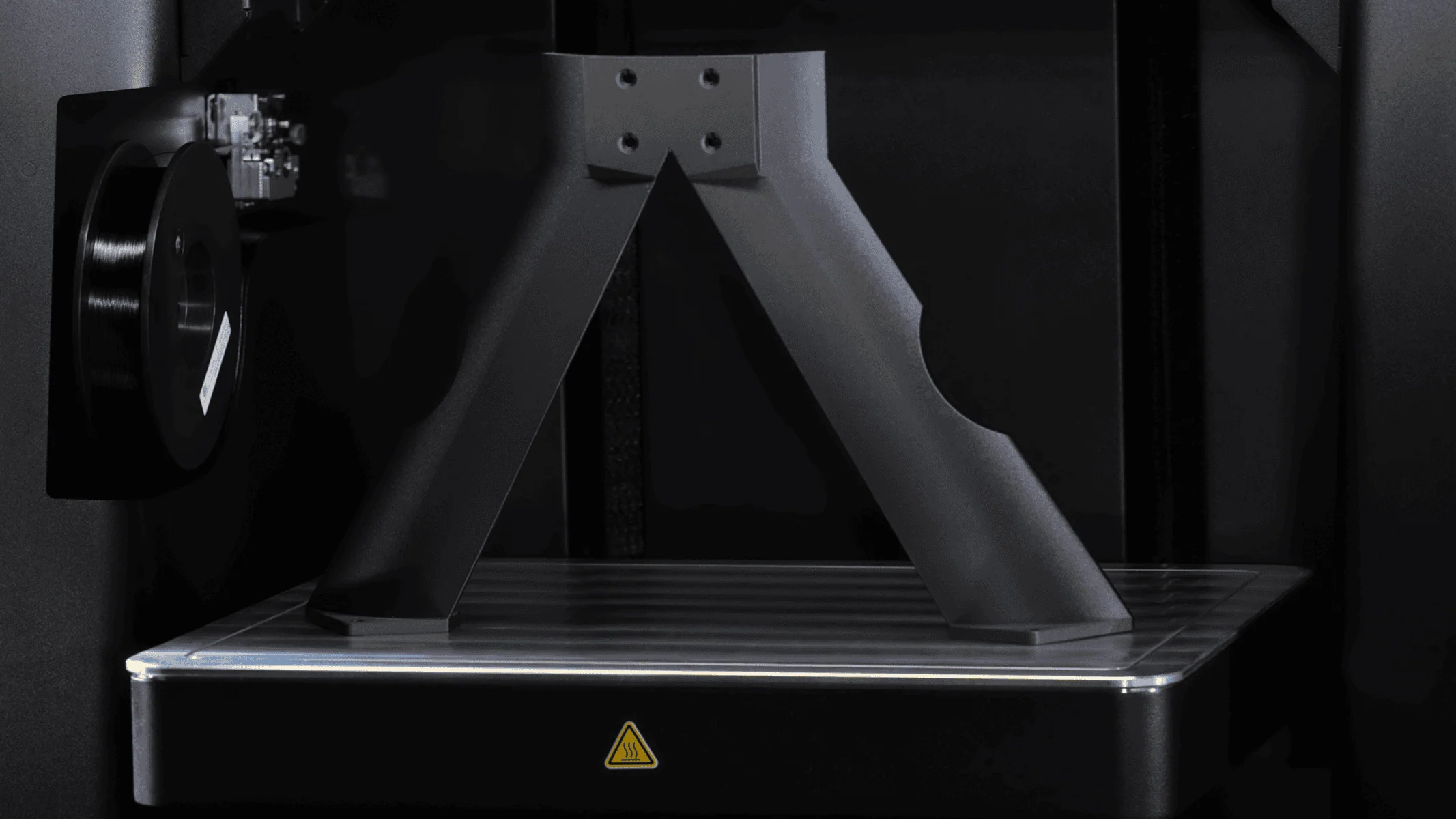

As industrial manufacturing requirements grow more complex, manufacturers are seeking versatile solutions that can meet a wide range of needs with a single system. This is where the Markforged FX10 stands out. As the first industrial 3D printer capable of producing both metal and continuous fiber-reinforced composite parts, the FX10 brings a new level of flexibility to the manufacturing floor while optimizing capital investment.

Initially introduced in Fall 2023 as an advanced composite printer, the FX10 quickly evolved beyond expectations. Markforged’s promise of modularity turned out to mean more than just interchangeable components—it represented a complete transformation of functionality. With a simple hardware switch and a quick calibration process, FX10 can transition into a fully equipped metal 3D printer. This makes it not just flexible, but a standalone manufacturing cell.

Two Processes, One System: FFF + CFR & Metal FFF

The FX10‘s true strength lies in its ability to unite two completely different additive manufacturing workflows in one system. On the composite side, it uses FFF (Fused Filament Fabrication) combined with CFR (Continuous Fiber Reinforcement) to create strong, lightweight parts. In this process, thermoplastic filament is reinforced in-layer with continuous strands of carbon fiber, Kevlar®, or HSHT fiberglass. The resulting parts deliver mechanical strength that rivals aluminum.

For metal printing, the FX10 uses Markforged’s Metal FFF process, which consists of three key steps:

Print: A filament filled with metal powder and bound in polymer is printed.

Wash: The “green part” is immersed in a solvent to dissolve the polymer binder.

Sinter: The part is sintered in a furnace and shrinks by approximately 20% to reach final density.

The entire process eliminates the need for loose metal powders, ensuring safe and user-friendly metal manufacturing on the shop floor.

Broad Material Compatibility, High Performance

In composite mode, FX10 supports materials like Onyx (polyamide 6), Onyx FR, and Onyx ESD, all of which can be reinforced with continuous carbon fiber, Kevlar®, HSHT fiberglass, or fiberglass. This enables manufacturers to produce parts that are lightweight, durable, and ready for functional use in demanding environments.

On the metal side, FX10 is compatible with 17-4 PH stainless steel, H13 and D2 tool steels, and copper. Most notably, the system also supports 316L stainless steel, available exclusively on FX10. This highly corrosion-resistant alloy is ideal for food processing, marine, and chemical applications.

A Truly Modular Hardware Architecture

FX10 was designed from the ground up to support its dual capabilities through a fully modular hardware design. Separate print heads are used for composite and metal manufacturing. The composite head includes a plastic nozzle and a fiber nozzle, while the metal head has nozzles for metal filament and ceramic release material. Both heads can be swapped using just two screws.

The material routing block located at the rear of the machine also changes depending on the selected mode. In composite mode, it merges four spool inputs into a single output. In metal mode, it routes materials to two separate outputs—one for metal filament, the other for ceramic release. This switch, along with the material tubes and other support parts, takes about 15 minutes.

Once the hardware is changed, FX10 runs a full calibration sequence—about an hour—during which built-in optical sensors and a laser micrometer scan every layer and confirm dimensional accuracy in real time. This provides in-process quality assurance with no extra measurement steps needed.

Smart Features Built for Manufacturing Environments

The FX10 is more than a printer—it’s a complete manufacturing tool designed to integrate seamlessly into busy industrial environments.

- The sealed drawer holds up to four 800cc spools, protecting material from humidity.

- The system automatically switches between spools during a print.

- Users can reload an empty spool without pausing the job.

With a responsive touchscreen interface, real-time sensor feedback, and automated calibration and switching systems, FX10 minimizes operator involvement and maximizes uptime and workflow efficiency.

Which Process for Which Part?

Composite manufacturing is ideal for:

- Large-volume components

- Rapid prototypes

- Jigs, fixtures, and end-of-arm tooling (EOAT)

- Parts requiring non-marring contact surfaces

Metal manufacturing is ideal for:

- High-temperature tooling

- Wear-resistant components

- Applications requiring electrical or thermal conductivity

Hybrid parts combine both:

- EOATs with carbon fiber frames and metal wear tips

- Composite fixtures with embedded metal surfaces

These hybrid strategies allow engineers to optimize cost, weight, and performance in a single part.

Digital Manufacturing, Physical Results

FX10 is tightly integrated with Markforged’s Digital Forge platform, enabling:

- Cloud-based part storage and access

- Centralized fleet monitoring

- Organization-wide collaboration and digital inventory

This means FX10 is not just a printer—it’s a complete digital manufacturing solution ready to support decentralized and on-demand workflows.

FX10 is ideal for:

- Manufacturers who need both composite and metal capabilities in one system

- Teams bringing fixture and tooling production in-house

- R&D departments moving from prototyping to end-use part manufacturing

- Users seeking powder-free metal printing with full density results

With FX10, your manufacturing becomes more flexible, more efficient, and future-ready.

Contact us today to request a demo or discuss how FX10 can support your operations.