What is LDM Technology? Advantages of Liquid Material Use in 3D Printing

#Aug 20, 2025

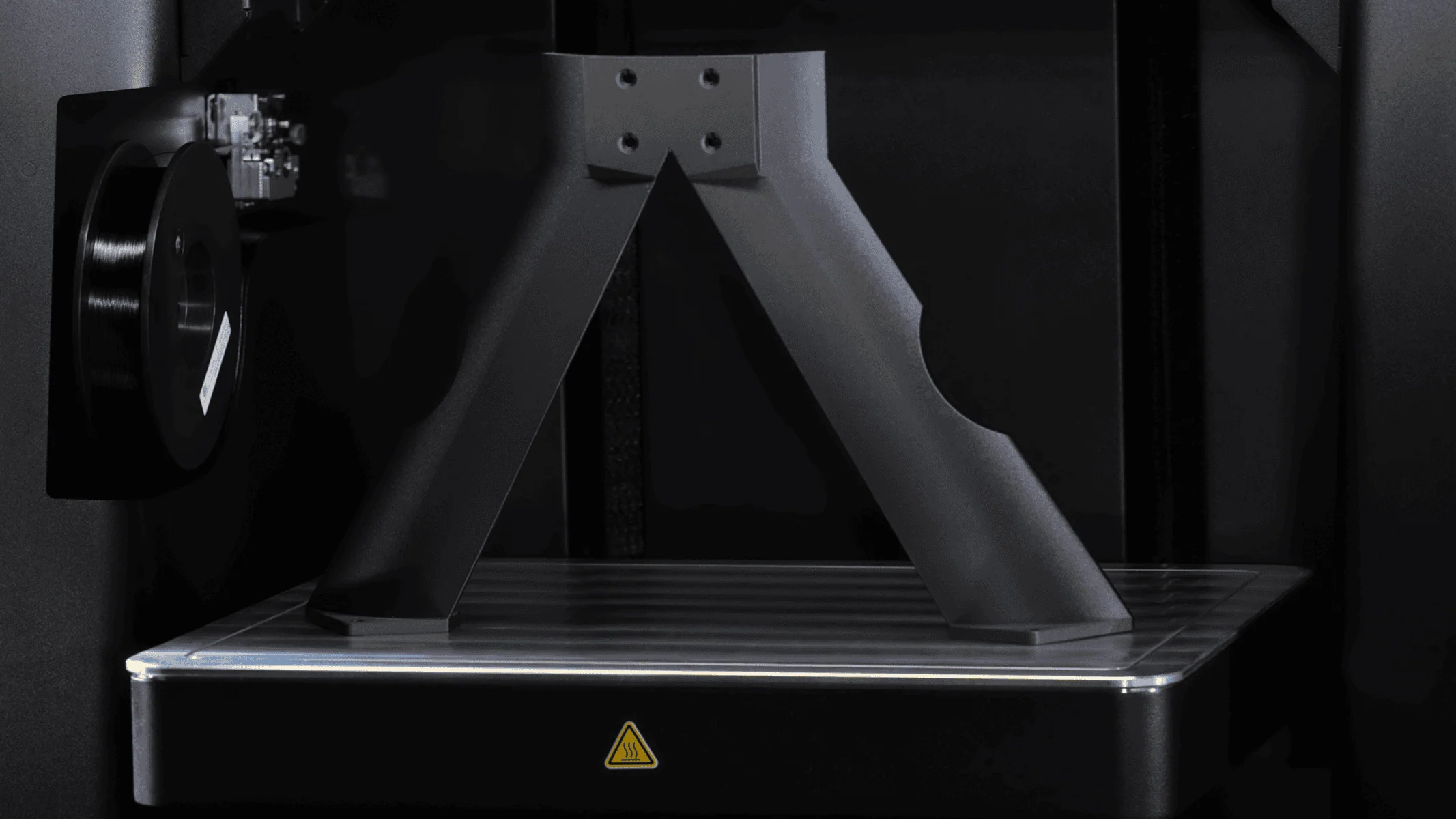

Liquid Deposition Modeling (LDM) is an innovative method in 3D printing technologies that allows for the production of three-dimensional parts by depositing liquid or semi-liquid materials layer by layer. In recent years, the LDM printing process has been preferred in a wide range of applications, from industrial manufacturing to medical uses, offering significant advantages for sustainable production.

1. Basic Principles of LDM Technology

LDM technology works similarly to traditional FDM (Fused Deposition Modeling) methods, but instead of plastic filament, liquid-based raw materials are used. In this method:

- Material is precisely deposited layer by layer through a special nozzle.

- Layers are cured by UV light or heat to form a three-dimensional structure.

- More fluid materials allow for the production of complex geometries and flexible parts.

These features make liquid material 3D printing especially advantageous in the production of biomedical implants, food manufacturing, and flexible prototypes.

2. How LDM Printing Differs from Other 3D Printing Technologies

There are various 3D printing methods such as SLA, SLS, and FDM. However, LDM printing stands out with the following differences:

- Material Variety: Silicones, biopolymers, and low-viscosity ceramics can be used.

- High Flexibility: Printing can be done at low temperatures, preventing damage to sensitive materials.

- Precision Details: Layer thickness can be finely adjusted, enhancing surface quality.

- Energy Efficiency: The use of lower energy helps contribute to sustainable production.

These advantages have made LDM technology indispensable, especially in the medical and electronics sectors.

3. Advantages of 3D Printing with Liquid Materials

3D printing with liquid materials provides both technical and environmental benefits to the production process:

- Flexible Material Use: Prototypes and medical implants resembling soft tissues can be produced.

- Waste Reduction: Materials are applied directly where needed, minimizing waste.

- Multi-material Printing: Different materials can be integrated within the same production process.

- Improved Mechanical Properties: More durable and lighter parts can be produced.

- Energy Efficiency: Up to 30% energy savings compared to traditional production methods.

These features reduce costs in industrial manufacturing while decreasing environmental impact.

4. Industrial Applications and the Future of LDM

LDM technology is applied across various industries, including automotive, aerospace, medical, and consumer electronics. Examples include:

- Medical: Custom prosthetics and implants.

- Electronics: Flexible circuit boards and sensors.

- Automotive and Aerospace: Lightweight and durable spare parts.

- Food: Moldable chocolate or gel-based products.

5. Professional LDM Solutions with 3D Promakim

3D Promakim, an expert in 3D printing, offers professional solutions with Liquid Deposition Modeling technology:

- High-precision 3D printing machines.

- LDM printing supported production solutions for industrial-scale applications.

- Technical support and consulting for special projects.

For more information and to bring your projects to life, contact Prodigma.

LDM Technology for Increased Efficiency in Industrial Production

LDM technology offers a flexible and sustainable production approach based on the use of liquid materials in 3D printing. Its success in industrial applications, combined with energy and material savings, is shaping the future of modern manufacturing.

If you want to transform your production processes with the latest technologies for LDM industrial applications, collaborate with 3D Promakim to stay ahead in the competition.