Industrial 3D Printer with Prototyping: A Revolution in Product Development

#Mar 20, 2025

In today’s competitive business world, the rapid and cost-effective development of new products offers a significant advantage. Industrial 3D printer technologies streamline this process, enabling designers and engineers to revolutionize the prototyping phase. Compared to traditional manufacturing methods, this technology is faster, more flexible, and cost-effective—making a substantial impact in various sectors from industry to healthcare.

In this article, we will explore in detail the advantages of prototyping with industrial 3D printers, their applications, and the value they bring to businesses.

What Is an Industrial 3D Printer and How Does It Work?

Industrial 3D printers are advanced devices that convert digital designs into physical objects using layered manufacturing technology. Unlike standard 3D printers, they are designed for large-scale production, can work with more durable materials, and offer high precision.

How They Work:

- Digital Modeling: Designers create a three-dimensional (3D) model using computer-aided design (CAD) software.

- Slicing: The software divides the model into layers and determines a production path for the printer.

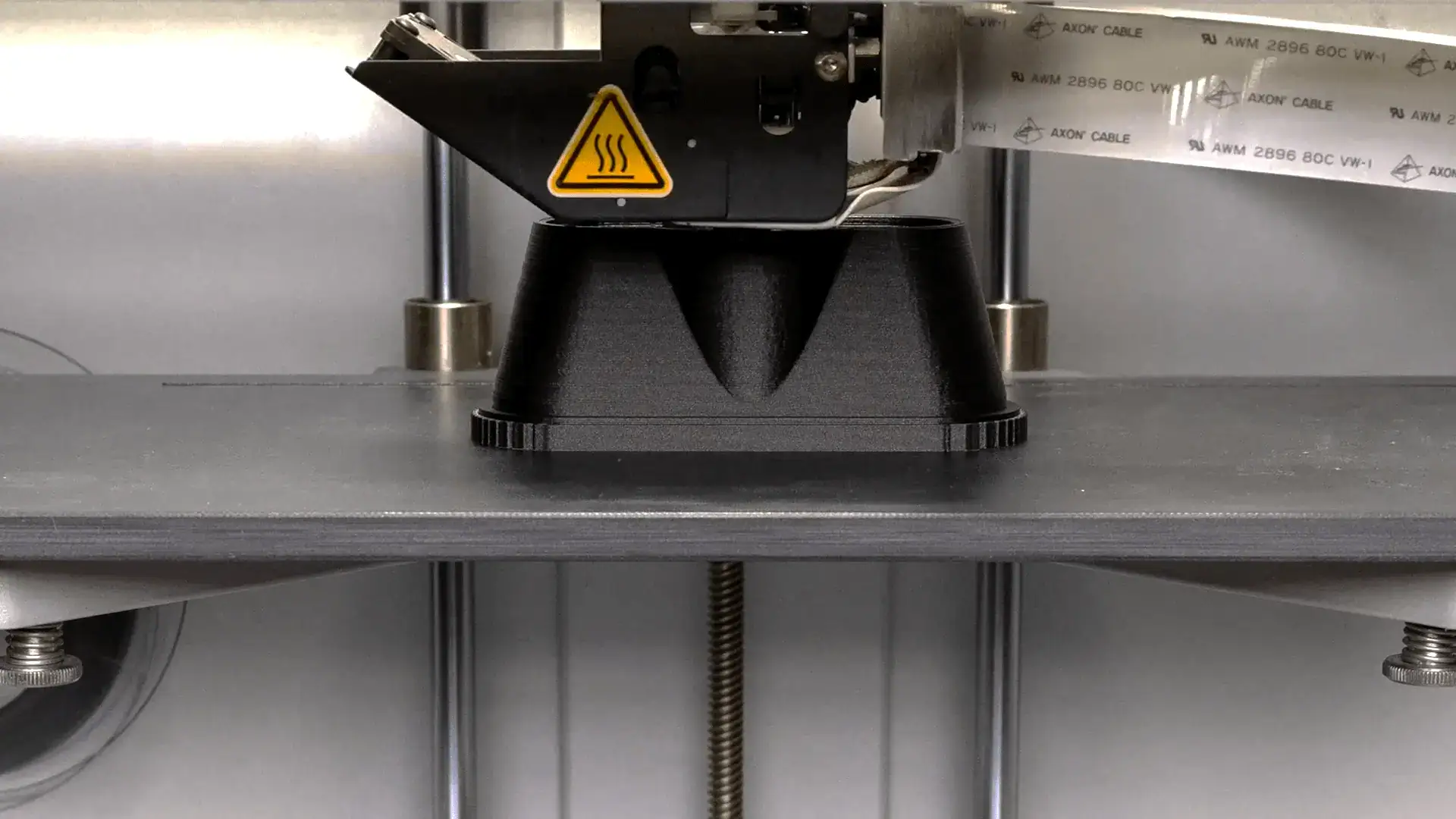

- Printing Process: The industrial 3D printer builds the physical object by adding material layer by layer.

- Post-Processing: If necessary, surface treatments, painting, or heat treatments are applied to complete the prototype.

This process significantly accelerates the product development cycle by being much faster and more cost-effective than traditional manufacturing methods.

The Role of Industrial 3D Printers in Prototyping

Prototyping is a critical phase in product development, allowing the final design to be tested before mass production. The use of industrial 3D printers makes this process more efficient, offering substantial benefits to product development teams.

Advantages in the Prototyping Process:

- Fast Production: A prototype that might take days or even weeks using traditional methods can be produced within hours using industrial 3D printers.

- Low Cost: Since there is no need for mold production, direct printing significantly reduces manufacturing costs.

- Design Flexibility: Complex and detailed designs are much easier to produce compared to conventional methods.

- Error Detection and Improvement: Prototypes can be tested immediately, allowing for quick identification of design flaws and swift revisions.

These benefits enable companies to bring products to market faster and gain a competitive edge.

Revolutionizing Production with Industrial 3D Printers

Beyond prototyping, industrial 3D printers are increasingly used in mass production. This technology, with its broad range of applications—from automotive to healthcare, aerospace to fashion—is driving major transformations in manufacturing processes.

Application Areas:

- Automotive: Utilized for rapid prototyping and the production of custom parts; for example, brands like General Motors and Ford employ industrial 3D printers to test engine components.

- Aerospace and Defense: Used in the production of lightweight and durable aircraft parts.

- Healthcare: The rising use of 3D printed prosthetics, dental devices, and tissue models produced through bioprinting.

- Architecture: 3D printed building models play a significant role in construction projects.

Thanks to the speed, cost efficiency, and design flexibility provided by industrial 3D printers, these sectors are optimizing their production processes and achieving greater efficiency.

Why Choose 3D Promakim?

3D Promakim is one of Turkey’s leading providers of industrial 3D printer solutions. With a wide range of products, technical support services, and innovative solutions, they help companies optimize their production processes.

Keeping up with the latest technologies in 3D printing, 3D Promakim offers customized solutions tailored for each sector. For professional support in product selection, training, and technical assistance, visit their contact page.

The Future of Product Development with Industrial 3D Printers

Industrial 3D printers are transforming both prototyping and mass production with their speed, cost benefits, and flexibility. By introducing innovations that traditional methods cannot match, companies can streamline their product development processes and secure a competitive advantage.

In the future, as 3D printer technologies continue to evolve, they will become a cornerstone of industrial manufacturing. Now is the perfect time to consider industrial 3D printer solutions to accelerate your product development and stand out in a competitive market!