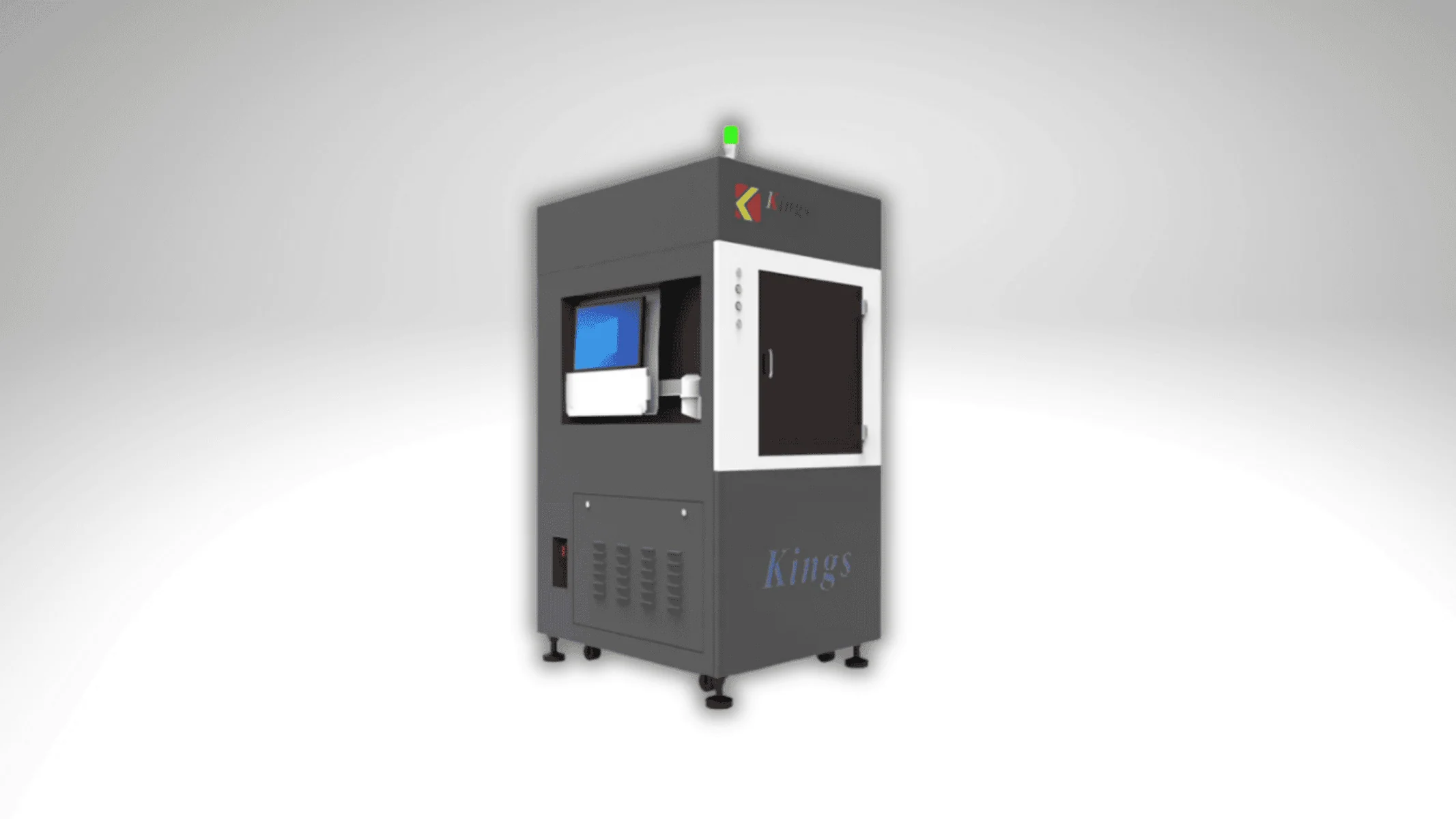

Kings SLA 450Pro: High-Precision, Large-Scale Manufacturing with Industrial-Grade SLA 3D Printing

#Jul 09, 2025

As industrial production processes continue to digitalize, the advantages of 3D printing technologies are becoming increasingly evident across sectors. Among them, Stereolithography (SLA) stands out for its surface quality and dimensional accuracy, making it a go-to solution for rapid prototyping and low-volume production. Developed by Kings 3D, the SLA 450Pro is an industrial-grade SLA 3D printer engineered for high-precision and large-format manufacturing. With its robust hardware, optimized optical system, and advanced software integration, the SLA 450Pro offers a balanced and powerful solution for demanding applications.

Maximum Productivity with Large Build Volume

The SLA 450Pro offers a generous build volume of 450 × 450 × 350 mm, enabling the single-pass production of large parts as well as the efficient batch printing of multiple small components. This scalability is a key advantage in industries such as automotive, medical, dental, and architectural modeling.

The printer’s rigid body structure (weighing approximately 720 kg) minimizes vibrations during operation, ensuring consistent print quality. Its marble-based recoater and build platform not only enhance thermal stability but also improve the accuracy of mechanical movement. This setup makes it ideal for continuous, high-precision manufacturing scenarios.

Advanced Laser and Scanning System

At the core of the SLA 450Pro is a 355 nm Nd:YVO4 ultraviolet laser, delivering over 300 mW of output power. Paired with a 0.08 mm laser spot diameter, it enables the creation of intricate features and fine-walled structures with micron-level precision.

The integrated galvanometric scanning system operates at speeds of up to 15,000 mm/s (15 m/s), significantly reducing print times even for large-scale projects and increasing overall production capacity.

Layer Thickness and Dimensional Accuracy

With a layer thickness range of 0.05 mm to 0.20 mm, the SLA 450Pro is capable of delivering outstanding resolution across a variety of applications. A dimensional accuracy of ±0.1 mm and repeatability of ±0.01 mm make it a reliable solution in industries where tight tolerances are critical, such as dentistry, orthopedic modeling, functional prototyping, and electronics enclosures.

Resin Compatibility and Material Flexibility

The SLA 450Pro supports a wide range of photopolymer resins, including rigid, semi-flexible, high-temperature, and application-specific materials. This material versatility allows seamless integration into workflows that require varied performance characteristics, especially in sectors such as:

- Dentistry: Orthodontic models, implant simulations, crowns, and bridges

- Medical: Anatomical models for surgical planning

- Jewelry: High-detail prototypes and master molds

- Automotive & Aerospace: Aerodynamic testing models and assembly fixtures

- Architecture & Art: Large, complex aesthetic models

Software Integration and Workflow Efficiency

The SLA 450Pro runs on Kings 3D’s proprietary software, compatible with widely used file formats such as STL and SLC. It offers Ethernet connectivity for network-based operations and is equipped with professional features such as:

- Automatic galvo alignment and laser calibration

- Real-time print preview and error reporting

- Job queuing and print scheduling

Thanks to its intuitive user interface, both seasoned technicians and new operators can quickly initiate prints. Print parameters can be adjusted according to resin type, optimizing layer thickness, exposure time, and scanning speed for each material.

Industrial Hardware and Low Maintenance

Designed for industrial use, the SLA 450Pro features a long-lasting mechanical structure that requires minimal maintenance. Its marble platform system provides excellent wear resistance and dimensional stability.

Key hardware components (such as the galvanometric mirrors, axis movement systems, and recoater unit)are engineered for precision and long-term reliability. The printer comes with a 2-year warranty, covering both the laser module and the main chassis. Kings 3D also provides a robust global service network and spare parts supply chain, ensuring uninterrupted operation for end-users.

Energy Efficiency and Environmental Compliance

The SLA 450Pro features an energy-efficient design, with optimized power consumption throughout the print cycle. Its high-efficiency UV laser and reduced print times help minimize energy usage.

The photopolymer resins used are in compliance with industrial safety and disposal standards, making the printer environmentally responsible and workplace-safe.

Application Examples

Automotive Industry: Prototypes of front panels, ventilation grills, and assembly jigs can be produced quickly and economically with the SLA 450Pro.

Healthcare Sector: Patient-specific implant guides, organ models, and educational simulation tools are manufactured with exceptional accuracy.

Education & R&D: Universities and research centers use the printer for design validation, rapid prototyping, and iterative testing in product development.

Balanced Performance in SLA Technology

The Kings SLA 450Pro combines dimensional precision, large build volume, user-friendly software, and industrial-grade hardware into a cohesive SLA platform that meets the demands of professionals across multiple sectors. Whether you’re in dentistry, engineering, architecture, or production workshops, this 3D printer offers an ideal balance of reliability, accuracy, and throughput.

Redefine your production quality with the Kings SLA 450Pro.

For more information, material compatibility details, or quotation requests, feel free to reach out to our team.