The First Industrial Metal and Composite 3D Printer

#Oct 24, 2024

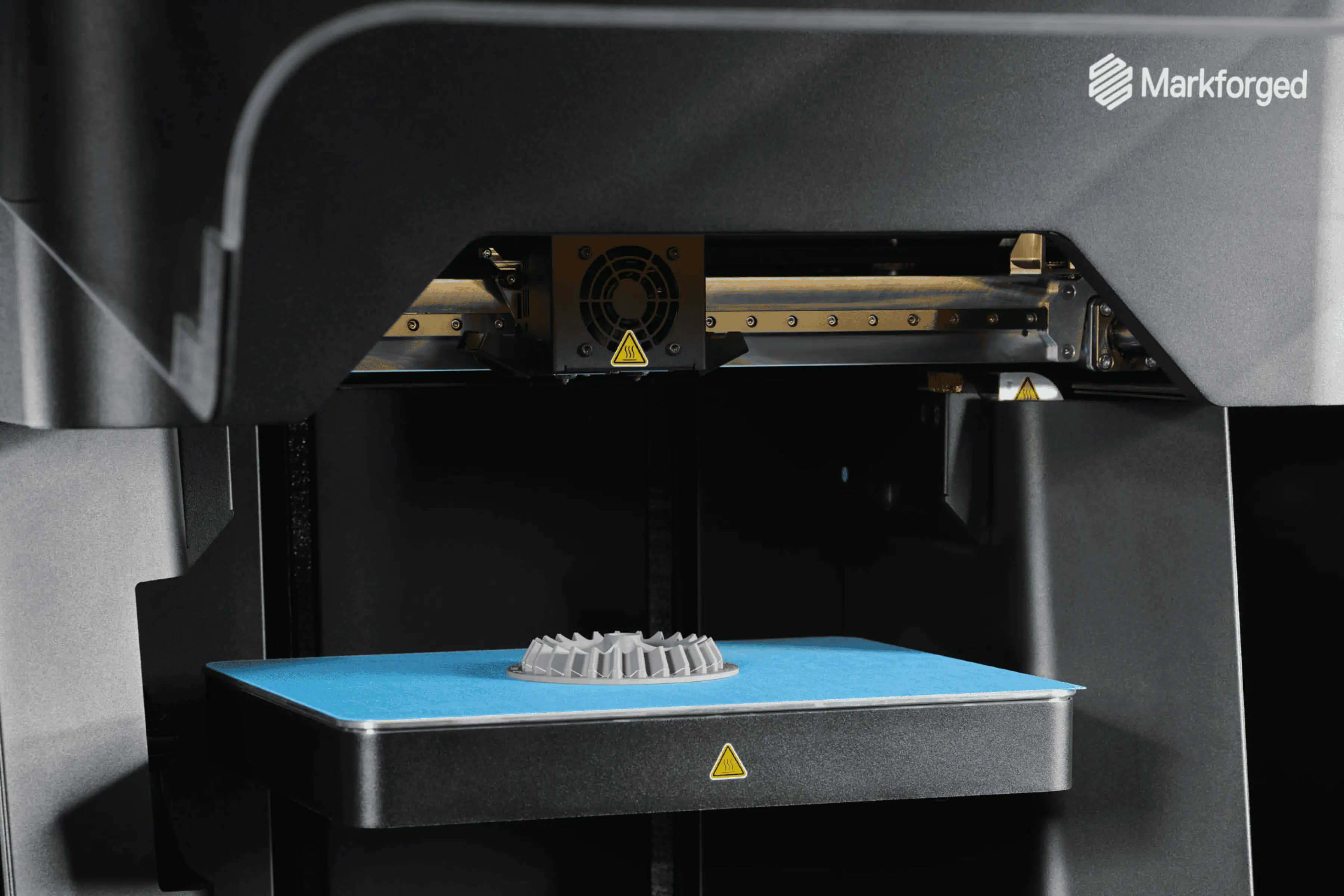

Meet the FX10: The First Industrial Metal and Composite 3D Printer

In the fall of 2023, Markforged introduced the FX10. The FX10 stands out with its modular design, enabling the production of both metal and composite parts. This modularity includes the Metal FFF (Fused Filament Fabrication) capability, making the FX10 the first industrial 3D printer capable of producing both composite and metal parts. Markforged designed the FX10 to integrate both composite and metal manufacturing processes, providing customers with flexibility in their production workflows. In this article, we explain the development process of the FX10 and how this printer has revolutionized industrial manufacturing.

Composite and Metal Printing Processes

The FX10 has both metal and composite printing capabilities. It benefits from two processes that combine FFF + CFR and Metal FFF. Markforged’s composite printers rely on two main stages: Fused Filament Fabrication (FFF) and Continuous Fiber Reinforcement (CFR). FFF is a printing process where thermoplastic filament is extruded layer by layer through a nozzle to create parts. CFR reinforces the parts with continuous fibers. CFR replaces the FFF infill, making the parts up to 10 times stronger and potentially replacing aluminum parts.

On the other hand, the Metal FFF process developed by Markforged allows the creation of near-net-shape metal parts without exposure to metal powders. This process consists of three steps:

- Printing: Polymerized filament made from metal powder is used to produce Green Parts. The polymer melts and extrudes from the nozzle, carrying the metal powder along with it. The parts are printed approximately 20% larger to account for shrinkage after processing.

- Debinding: The Green Parts are soaked in a solvent to dissolve the polymer binder. After this process, the parts are referred to as “Brown Parts.”

- Sintering: The Brown Parts are sintered in a furnace, transforming them into fully metal parts. During sintering, the parts shrink by approximately 20% and achieve their final shape.

Overcoming the Challenges of Metal and Composite Printing

The fundamental incompatibility between metal and polymer filaments made it challenging to combine these two printing processes. While polymer filaments require sealed material pathways to protect from moisture, metal filaments, due to their brittle nature, require special handling. To resolve this, Markforged engineers had to reformulate the metal filaments. Instead of using brittle filaments similar to Metal Injection Molding (MIM) feedstock, they developed their own optimized polymer binder for 3D printing.

The resulting flexible filaments were easier to manage and, most importantly, could pass through feed tubes without breaking. The first flexible filament, Copper, was launched in 2020, followed by popular steel types like 17-4PH v2, H13 v2, and D2 v2. After FX10’s metal capability comes online, 316L stainless steel will also be released.

How Does It Work?

The FX10 is designed with the understanding that metal and composite filaments require completely different hardware. Therefore, the key components of the print engine are modular and interchangeable.

-

Print Head: There are separate print heads for composite and metal. The composite print head has nozzles for plastic and fiber, while the metal print head has nozzles for metal filament and ceramic release material. The print head can be removed and replaced with just two screws.

-

Material Routing Block: This block feeds four material tubes into the print head. For composite printing, the tubes are routed into a single outlet, while for metal printing, they are routed into two outlets—one for metal filament and one for ceramic release material.

-

Material Tubes: Dedicated material tubes are used for each filament type, preventing cross-contamination between metal and composite filaments.

In addition to these components, auxiliary parts such as the print sheet, purge bin, and spool holder must also be changed. The full transition process takes approximately 15 minutes, after which the machine performs a one-hour calibration routine. The FX10 allows for a complete transition between metal and composite printing in less than two hours.

The FX10 represents a revolutionary printer capable of producing both metal and composite parts, transforming industrial manufacturing. Its modular design speeds up production processes and reduces costs. The flexibility and speed advantages of composite printing are combined with the durability and heat resistance of metal. The FX10, suitable for producing both large and complex parts, delivers speed, efficiency, and quality to factories. For companies looking to position themselves in the future of manufacturing, the FX10 is the ideal solution to enhance production capacity.